WholesalePallets.com

LLC

WholesalePallets.com

LLC

WholesalePallets.com

LLC

WholesalePallets.com

LLC

![]()

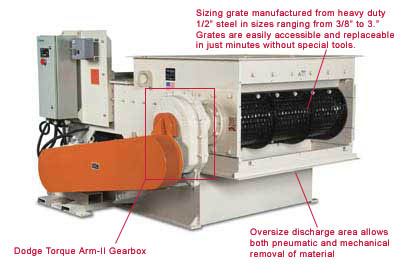

MP Series Slow Speed Ram Fed Grinders

|

The MP Series Grinder Gives You More | |

| The MP Series grinders give you an unbeatable choice for

American-made quality, performance and enduring value. Our grinders are

quiet, use less power, produce minimal dust, and reduce your manpower

requirements for even more savings. Other advantages include:

|

|

|

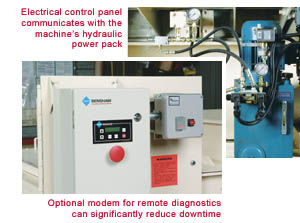

Brains and Brawn - A State-of-the-Art Control

Package

|

One of the most distinct advantages of the MP Series

grinder is its "brains" - the ability of the electrical control panel to

communicate and/or work in unison with the machine's hydraulic power pack.

The result is optimal grinding performance every time. One of the most distinct advantages of the MP Series

grinder is its "brains" - the ability of the electrical control panel to

communicate and/or work in unison with the machine's hydraulic power pack.

The result is optimal grinding performance every time.

With too little force, full grinding capacity is never achieved. With excessive force, the rotor can jam. The MP Series control system continuously monitors current and signals the ram to retract when a predetermined amperage level is exceeded. In addition, the hydraulic power pack features a variable speed control which allows the ram cycle to be set at the appropriate speed for the type of material being processed, for example hard or soft wood, dry or green, pallets, stumps, etc. A pressure relief valve enables the ram to pause during the forward stroke when heavy grinding is sensed. When the pressure reduces the ram resumes its forward movement, eliminating nuisance cycling and maximizing efficiency. The control system also "thinks" about protecting your equipment. If tramp metal finds its way into the grinder, the unit will be instructed to shut down after three auto-reverses within a preset time frame. This virtually eliminates the potential for damage to the grinding rotor. |

|

Testing Services and Performance Guarantee |

Schutte-Buffalo Hammer Mill offers testing services

with the MP Series at no extra charge. We provide free test grinding and

videotaping of your material being ground. With over 5,000 wood grinding

installations, our experienced engineering team has the expertise to

determine the proper equipment for your specific application. Schutte-Buffalo Hammer Mill offers testing services

with the MP Series at no extra charge. We provide free test grinding and

videotaping of your material being ground. With over 5,000 wood grinding

installations, our experienced engineering team has the expertise to

determine the proper equipment for your specific application.

With our exclusive Performance Guarantee you eliminate the risk of purchasing the wrong equipment for your needs. And if you have a unique application, you can provide us a sample for testing to determine the right model for your specific needs. Schutte-Buffalo Hammer Mill will then guarantee the equipment we build for you will perform as our test report indicates and will match the sample product returned to you for evaluation. Your equipment is guaranteed to produce the required product size at or above the desired throughput rate. |

MP Series Specifications

| Model | HP | Rotor Diameter | Capacity* | Weight | Grinding Deck** |

| MP-40 | 40-60 | 15" | 3-7,500 lbs. | 8,500 | 52" x 52" |

| MP-75 | 60-75 | 15" | 5-16,000 lbs. | 9,600 | 58" x 52" |

| MP-100 | 75-100 | 20" | 7-20,000 lbs. | 12,300 | 66" x 66" |

| MP-125 | 100-125 | 20" | 8-25,000 lbs. | 13,500 | 72" x 66" |

|

Electrical Controls

|

Hydraulic Power Pak

|

*Capacity will vary depending on horsepower, screen size,

and type of material being processed. Specific throughput capabilities will be provided following an analysis of each application. **Measurement taken at floor of grinding chamber. Hoppers available in various sizes to accommodate every requirement. |

Schutte-Buffalo Hammer Mill

Deliver Quality

As a leader in size reduction equipment,

Schutte-Buffalo Hammer Mill offers a full range of products backed by expert

service and support to meet all your wood processing needs.

As a leader in size reduction equipment,

Schutte-Buffalo Hammer Mill offers a full range of products backed by expert

service and support to meet all your wood processing needs.

This includes our Industrial Hammermills that can be joined with the MP Series to meet your fine grinding needs. These finish where the MP Series leaves off, creating a uniform, first quality sawdust useable for compost, animal bedding, briquette manufacturing and more.

Our expert representatives offer the best advice on the equipment you need for your specific applications. They can help you select from a full line of grinders and hammer mills for wood processing applications including:

Fill out our online quote form or Call 1-888-7PALLETS for more information. Find out how much you can save through us.

click to see specs on other grinders...

Tel (888) 7PALLETS (1-888-772-5538) email service@wholesalepallets.com

Request a Quote | Company Info | Pallet Info | Products | Email Us | Return to Home Page

© 2001 - 2011 WholesalePallets.com LLC